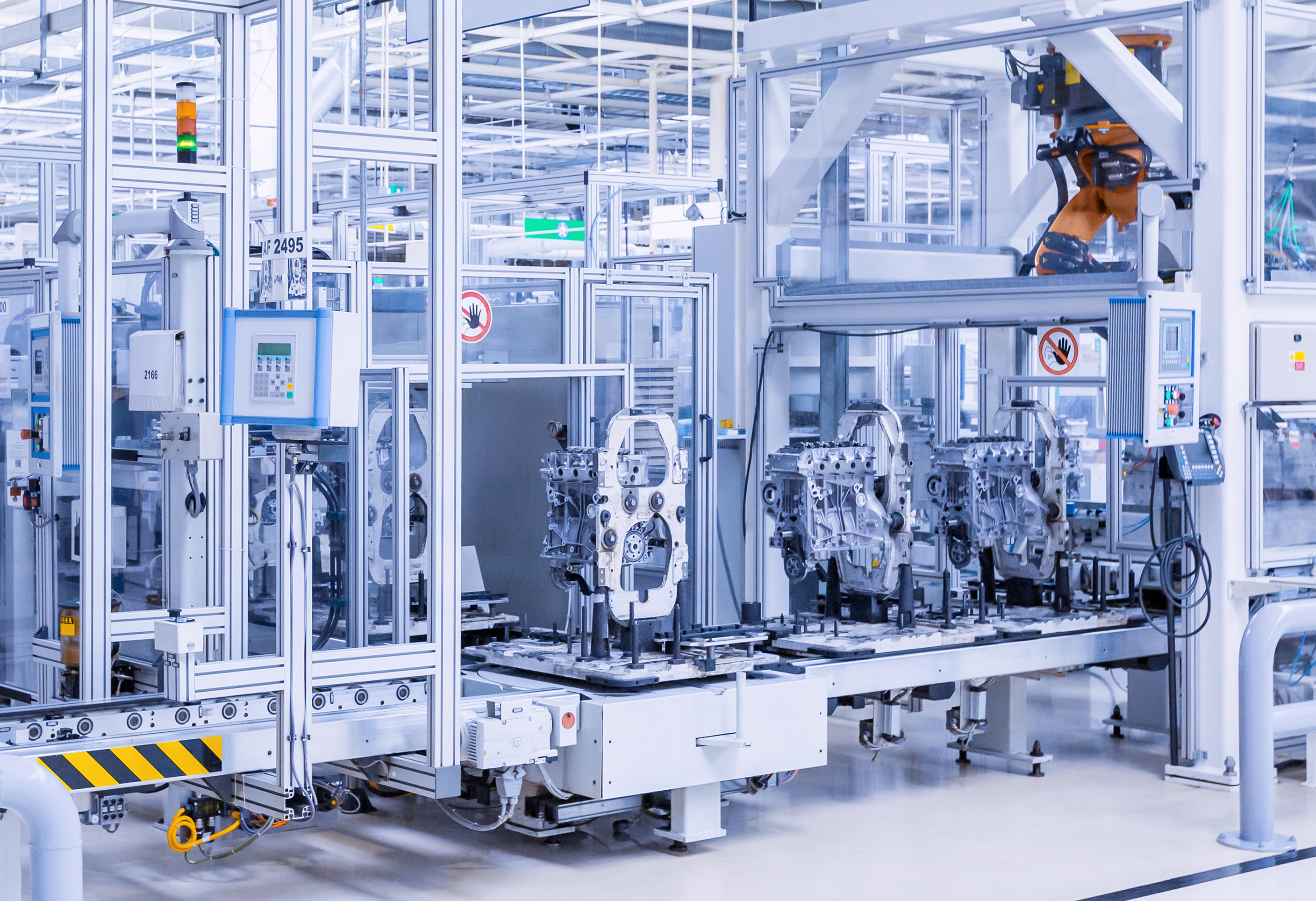

Give your plant an upgrade!

Bytefabrik Manufacturing Analytics feels the pulse of your plant - through AI-based evaluation of control and sensor data, you get a 360-degree analysis of all processes and process parameters.

You save costs through higher plant efficiency, lower maintenance costs and consistent product quality.

The best data basis is your machine control.

Want to really get to the bottom of the often complex causes of poor asset performance?

Plant control systems have a large amount of data that is often used purely for control purposes.

Our software simply connects to your control system (e.g. Siemens, OPC-UA) or directly to sensors and from then on senses any change, no matter how small, that affects your production quality.

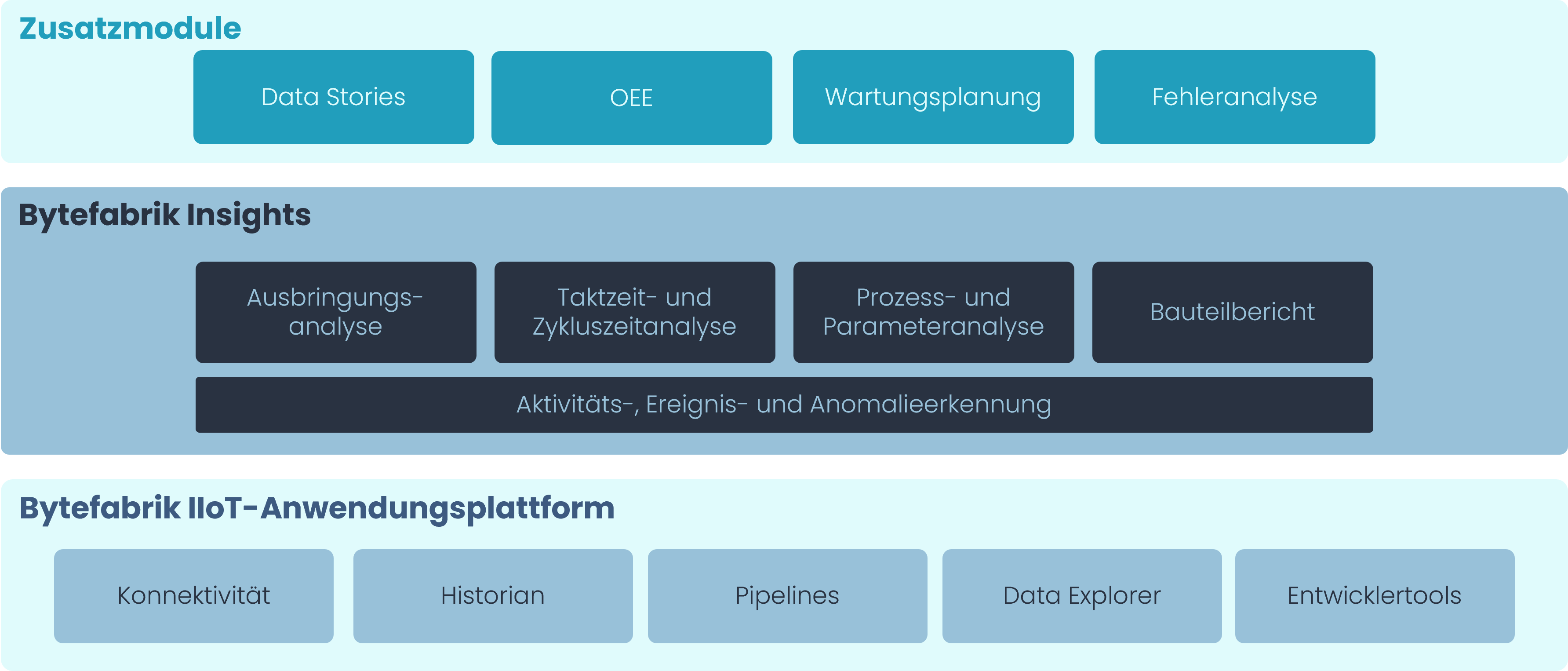

Modular structure

Manufacturing processes rarely resemble each other, and thus the needs for data analysis also differ.

Bytefabrik Manufacturing Insights is built on our IIoT application platform and is a flexible solution that fully adapts to your needs.

You can start small and gain initial insights into data-driven production improvement. But our solution also offers many add-on modules for the different requirements of your employees, e.g. representation of OEE or planning tools for maintenance staff.

Und wenn Sie etwas nicht finden: Unser System ist jederzeit erweiterbar - entdecken Sie die Möglichkeiten unserer Anwendungsplatform!

Much more than a dashboard.

But just as simple.

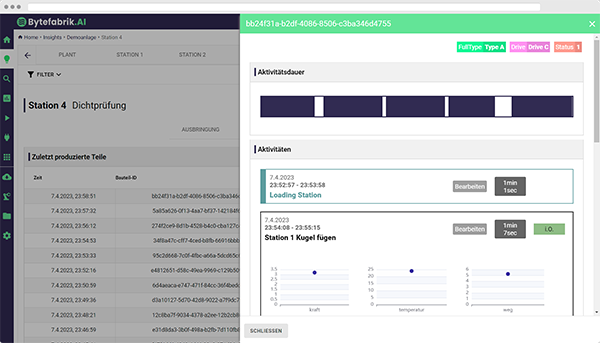

Pure visualizations usually create only limited insights. Our software uses a unique method to derive events, activities and behavior models from raw data for each station and process.

This forms the basis for real-time analyses that detect not only key figures, but also deviations and anomalies - clearly prepared for process engineers, quality managers or maintenance staff!

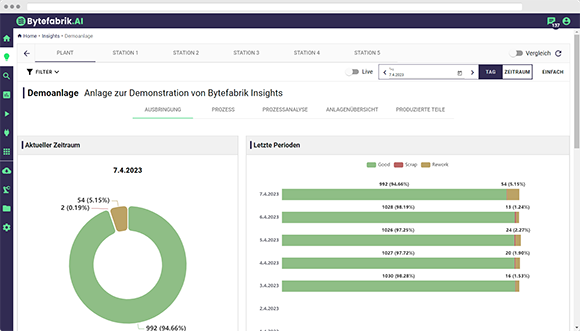

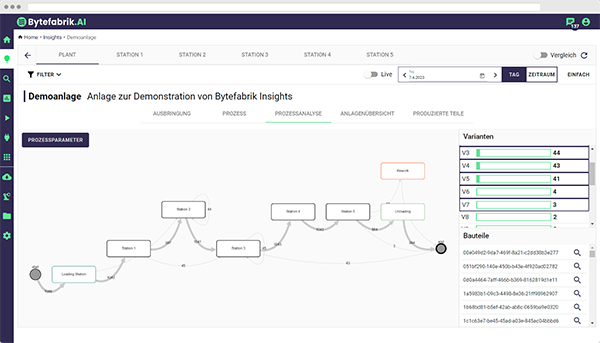

Output and cycle time analyses

All yield figures at a glance - per plant, station and visually prepared according to your plant layout.

- All IO, NIO and rework parts at a glance

- Cycle and cycle times for each plant, station and process

- Easy filtering and searching by layers, assemblies, metadata, environment data, times

- Storage of setpoints per process and type

- Automatic deviation detection and alarming

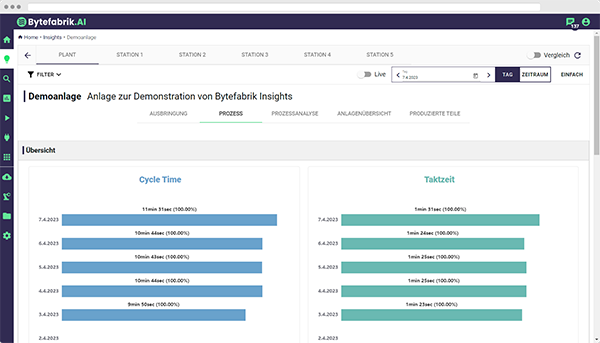

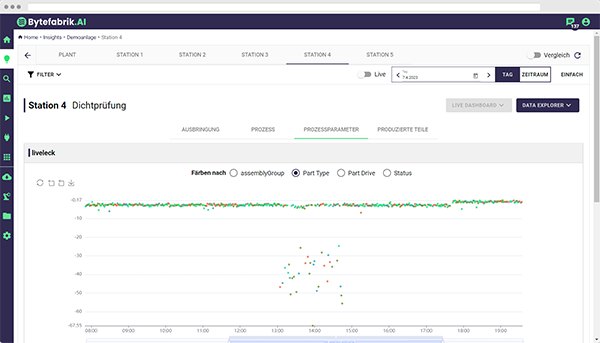

Analyze process parameters

Process parameters such as force, displacement, temperatures or leakage values are crucial for process quality. Our solution captures all process parameters, detects creeping trends and patterns that indicate future limit violations, and helps process engineers implement process improvements in a data-driven manner.

- Continuous analysis of all process parameters for all product types

- Predictive detection of impending limit value violations

- Intuitive process display with aggregated display of all produced parts

- Preparation of all process parameters per process in order to identify trends leading to efficiency losses at an early stage

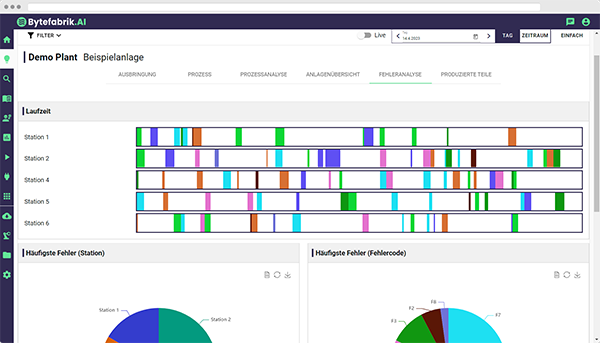

Error analysis

In complex automated systems, system and machine errors that cause temporary system downtime are not uncommon. Causes are, for example, worn wear parts, faulty workpiece carriers or programming errors.Often, such errors are manually recorded and evaluated in Excel lists. Manufacturing Insights automatically generates reports, indicates error sources and supports the elimination of common error sources.

- Analysis and processing of error codes directly from the control system

- Representation of the temporal distribution and the most frequent errors

- Separate display according to assemblies and stations

- Manual recording of troubleshooting measures

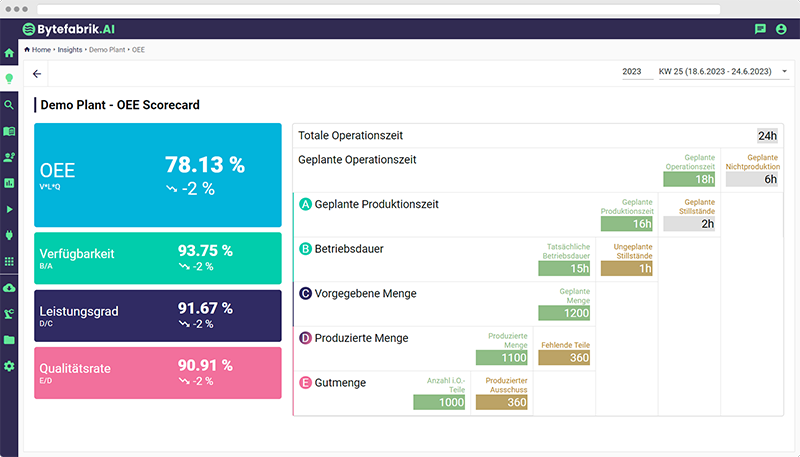

OEE

As a decision maker, you do not need a detailed display of all process parameters, but a clear and always up-to-date situation picture.

Our OEE module is your new window into production! Clearly displayed in the form of a scorecard, you can see not only the OEE at a glance, but also changes and a breakdown of the individual factors such as availability, quality rate and performance level, as well as all planning data.

With the OEE module, you can see at a glance which equipment is running well and which equipment needs your attention.

Product report

Not only you, but also your customers place the highest value on consistently high and verifiable product quality. Our software records all information on the process (e.g. run times and cycle times) and process parameters (e.g. compliance with limit values or force-displacement curves) for each individual part produced.

The component report provides you with an intuitive search mask to retrieve this information at any time - if desired, even with selective release as proof of quality for your customers!

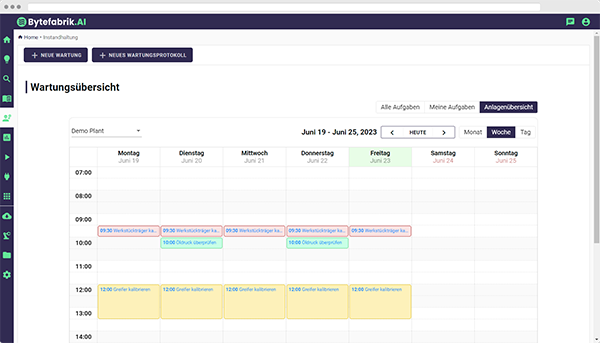

Planning and collaboration tools

The best insights are of no use if they are not implemented. We want to support your employees in integrating data-driven decision making into their daily routine and reducing the use of paper.

Our planning and collaboration tools enable direct improvements to the work process by digitally displaying actions such as maintenance actions or best practices, and integrate seamlessly with your existing processes.

Wartungsplanung

Digitally schedule maintenance calls in a simple web-based interface by schedules, assets, and categories, and create maintenance logs.

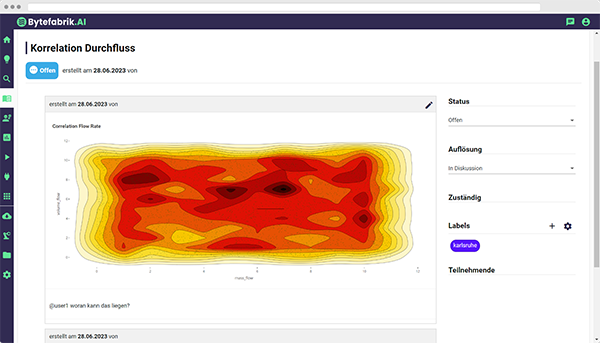

Data Stories

Your employees' knowledge is their most valuable asset - Data Stories create efficient communication between stakeholders when analyzing problems and automatically create knowledge manuals for each asset. They reduce onboarding times and ensure that valuable knowledge stays in your company and does not fluctuate.

Learn more